3D Concrete Printing (3DCP) in the Building & Construction

Intro

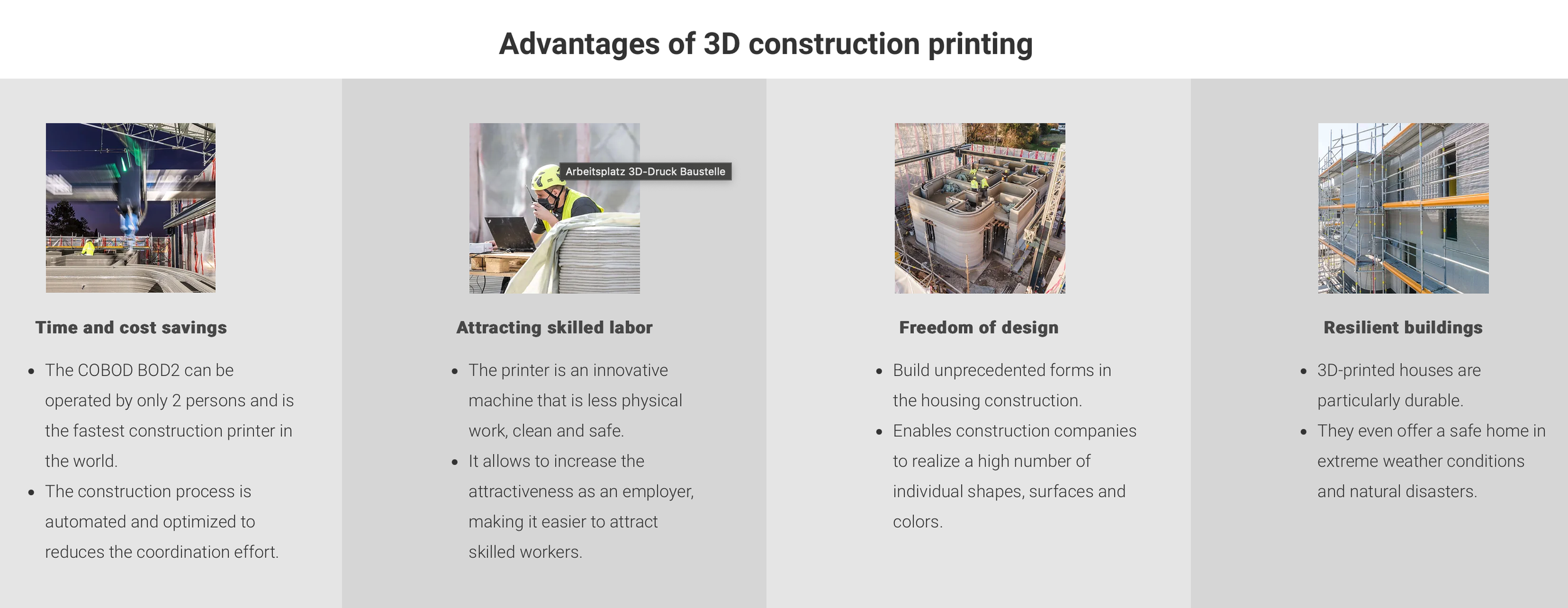

As building technology continues to advance, 3D concrete printing is poised to transform and potentially replace many aspects of manual construction in the future. This innovative method offers a more cost-effective, efficient, and sustainable approach to building. Unlike traditional construction, 3D concrete printing utilizes specially formulated concrete designed for fast, stable extrusion through the printer’s nozzle and rapid air curing while still incorporating standard steel reinforcement for structural integrity.

Why Choose Us?

We are expanding our production line with the introduction of concrete 3D printing technology, positioning us at the forefront of modern construction and design. This breakthrough enables us to create durable, sustainable, and cost-efficient building components and structures with exceptional speed and precision. By integrating architectural expertise with advanced fabrication, we offer clients smarter and more efficient solutions that reduce labor costs, minimize waste, and accelerate project timelines making Umbaji the ideal partner for future-focused construction and design.

3D Concrete Printing Process

What to expect?

How a 3D Concrete Printer Works

When a client approaches Umbaji by KW for a 3D concrete printing project, they expect a professional, design-driven, and technology-backed experience that delivers both innovation and reliability. Here’s what clients typically expect from Umbaji at each stage of their 3D concrete project:

🧱 1. Design & Concept Development

Translate their vision into a feasible 3D-printed concrete design — whether it’s a home, pavilion, façade, wall system, planter, or structural component.

Provide architectural drawings, renderings, and 3D models that reflect sustainability, beauty, and precision.

Offer customization in design (geometry, texture, scale, and finishes).

Ensure designs meet structural and local building code requirements where applicable.

⚙️ 2. Technical Expertise & Feasibility

Conduct feasibility assessments — identifying site conditions, print area requirements, and material behavior.

Recommend the best concrete mix formulations (e.g., proprietary 3D printing mortar, fiber-reinforced cement) for strength and smooth extrusion.

Use parametric modeling and BIM tools to optimize efficiency and reduce material waste.

🏗️ 3. 3D Printing Execution

Use state-of-the-art 3D concrete printers with precision and consistency.

Handle on-site or off-site printing logistics, ensuring fast and clean construction.

Maintain quality control during every layer of printing for accuracy and durability.

Coordinate with other trades (CNC, laser-cut templates, reinforcement placement) for hybrid fabrication.

🌿 4. Sustainability & Innovation

Incorporate eco-friendly materials and minimize waste through additive manufacturing.

Explore energy-efficient design solutions, such as thermal mass, solar integration, or green roofs.

Support LEED and green certification goals for sustainable projects.

🧩 5. Finishing & Post-Processing

Provide surface finishing, sealing, or color treatments for aesthetic and functional needs.

Integrate printed parts with metal, glass, or timber elements when needed.

Offer CNC and laser engraving options for signage, texture, or branding details.

📑 6. Project Management & Delivery

Deliver clear project timelines, cost estimates, and milestone updates.

Provide end-to-end coordination, from digital file preparation to on-site assembly.

Ensure safety, compliance, and documentation for all processes.

Deliver the final product on time, within budget, and aligned with design intent.

🌍 7. Experience & Vision

Be a trusted innovation partner — blending design, architecture, and technology.

Offer a turnkey solution: concept → prototype → full-scale build.

Demonstrate leadership in modern construction through creativity, craftsmanship, and sustainability.